In today’s competitive business landscape, the choice of packaging plays a crucial role in operational efficiency and product presentation. Among various packaging solutions, the Embossing Vacuum Bag has emerged as a preferred option for many businesses due to its unique benefits. According to a recent market report from Packaging Strategies, the demand for vacuum packaging has soared by 20% since 2021, driven largely by the need for enhanced product shelf life and reduced spoilage. This upward trend reflects the growing recognition of innovative packaging techniques that not only protect products but also elevate brand image.

Industry expert Dr. Linda Martell, a prominent figure in the packaging sector, emphasizes the transformative power of the Embossing Vacuum Bag, stating, “Utilizing embossed vacuum technology not only preserves the freshness of products but also attracts customers with its appealing design.” This dual advantage of functionality and aesthetics positions businesses to not only safeguard their offerings but also capture consumer attention in a crowded marketplace. With the growing emphasis on sustainability and efficiency, the adoption of Embossing Vacuum Bags is a strategic move that can drive long-term success for businesses aiming to optimize their packaging solutions.

Embossing vacuum bags are a game changer for businesses seeking to enhance product protection and longevity. These bags create a tight seal through a unique embossing process that strengthens the connection between the bag and the product inside. By effectively removing air and preventing moisture penetration, embossing vacuum bags guard against spoilage, damage, and contamination, ensuring that products remain in optimal condition during storage and transport.

Tip: When selecting embossing vacuum bags, consider the thickness and material. Thicker bags offer better puncture resistance, while high-quality materials can enhance durability and flexibility, adapting to various product shapes.

Moreover, the investment in embossing vacuum bags can lead to significant cost savings in the long run. Products that are better protected require less frequent replacements due to damage, ultimately contributing to improved customer satisfaction and brand reputation. Enhanced shelf life also means products can be stored longer, giving businesses the flexibility they need to manage supply effectively.

Tip: Always test the vacuum sealing process with your specific products to ensure a perfect fit and seal. This will help identify any adjustments needed for optimal performance and maximize the benefits of your packaging solutions.

| Benefit | Description |

|---|---|

| Enhanced Product Protection | Embossing vacuum bags provide a secure barrier against dust, moisture, and physical damage. |

| Improved Longevity | These bags help extend the shelf life of products by reducing exposure to air and contaminants. |

| Cost-Effective | Using embossing vacuum bags can lower costs related to damages and product returns. |

| Space-Saving | These bags minimize storage space by compressing items tightly. |

| Customizability | Embossing vacuum bags can be tailored to fit specific product dimensions and branding needs. |

| Increased Visibility | Clear bags allow consumers to see products while still providing protection. |

| Sustainability | Many embossing vacuum bags are made from recyclable materials, promoting eco-friendliness. |

| Reduction in Spoilage | Vacuum sealing reduces exposure to air, which can contribute to spoilage. |

| Enhanced Branding | Custom printed vacuum bags can improve brand visibility and recognition. |

| Versatility | Suitable for a wide range of products across various industries. |

Embossing vacuum bags offer a remarkable solution for businesses seeking to enhance the shelf life of their products. The effective moisture and air barrier created by these bags significantly slows down the deterioration process, ensuring that items remain fresh and appealing to customers for an extended period. By reducing exposure to air and humidity, businesses can minimize spoilage, enhance flavor profiles, and maintain the nutritional value of food products, ultimately leading to improved customer satisfaction.

When utilizing embossing vacuum bags, it’s essential to consider the material's compatibility with your product types. Tip: Always test a small batch of your product in the bags to ensure no adverse reactions occur. Another important aspect is the sealing technique used; a strong seal is crucial for maximizing the air barrier effect. Tip: Invest in a quality vacuum sealer that is specifically designed for use with embossed bags, as this will guarantee the best results in preserving your items.

Moreover, these vacuum bags can streamline your packaging process. The lightweight nature of embossed bags reduces shipping costs, while their customizable sizes accommodate various product dimensions. Tip: Use labeled samples of your vacuum-sealed products for marketing purposes, showcasing their extended shelf life, to attract more customers and demonstrate your commitment to quality.

Embossing vacuum bags offer a multitude of benefits for businesses, particularly in terms of cost-effectiveness. By minimizing excess material usage through their innovative design, these bags significantly reduce waste. The embossed surface creates channels that allow air to escape more efficiently, enabling a tighter seal without the need for bulky packaging. This not only saves resources during production but also leads to lower disposal costs, as businesses generate less waste over time.

Additionally, the compact nature of embossed vacuum packaging allows for more efficient storage solutions. When items are vacuum-packed, they occupy less space, which translates into reduced storage costs. Businesses can optimize their warehouse layouts, accommodating more products in less space. This efficient use of space can enable companies to lower rent expenses or shift their inventory more swiftly, enhancing overall operational efficiency. By leveraging embossed vacuum bags, businesses can achieve significant savings both in waste management and storage, ultimately leading to improved profitability.

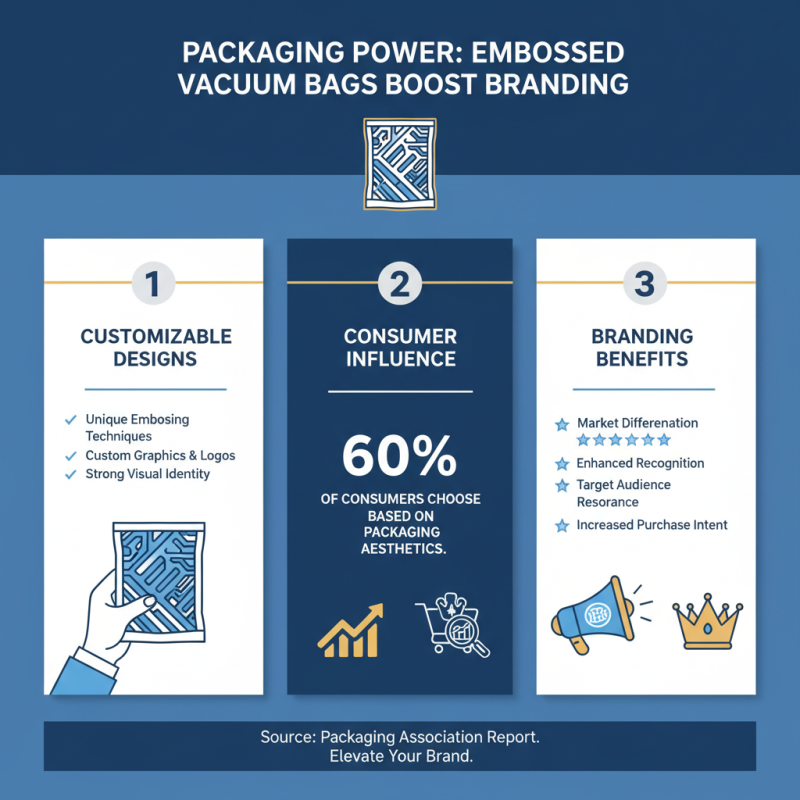

Customizable bag designs play a crucial role in enhancing branding opportunities for businesses that utilize embossing vacuum bags. According to a report from the Packaging Association, nearly 60% of consumers make purchasing decisions based solely on packaging aesthetics. This statistic highlights the importance of eye-catching designs that can differentiate a brand in a crowded marketplace. By incorporating unique embossing techniques and custom graphics, businesses can create a strong visual identity that resonates with their target audience, building brand recognition in a powerful way.

Tips for effective branding with embossing vacuum bags include keeping designs simple yet memorable. Utilizing your brand's color palette and logo prominently can help ensure that customers instantly associate the packaging with your products. Additionally, experimenting with textures and finishes can add a tactile element that enhances the overall customer experience, thus fostering brand loyalty. Industry research indicates that brands that focus on customized packaging can see an increase in customer engagement by up to 30%.

Moreover, embracing sustainability in design can further strengthen a brand's reputation. Using eco-friendly materials for embossing vacuum bags not only appeals to environmentally conscious consumers but also positions your brand as a leader in sustainable practices. This strategic approach, supported by data from the Global Packaging Trends report, suggests that 75% of consumers are more inclined to purchase from brands utilizing sustainable packaging solutions.

Embossing vacuum bags have emerged as a game-changer in the logistics industry, significantly enhancing the efficiency of shipping and handling processes. According to a report by the International Packaging Association, businesses using vacuum packing methods can reduce shipping volume by up to 30%, which not only cuts down on transportation costs but also minimizes environmental impact due to lighter packages. This efficiency ensures that products are protected from damage during transit, thereby reducing return rates and improving customer satisfaction.

To maximize the benefits of embossing vacuum bags, companies should consider implementing them for various product categories. For example, fragile items like glassware can be securely packed to withstand the rigors of shipping. Additionally, utilizing vacuum bags for perishable goods can extend shelf life, ensuring food stays fresh during transport.

Tip: Regularly analyze your delivery metrics to identify areas of improvement. By integrating vacuum technology into your packing processes, you can fine-tune your operations further and enhance overall productivity.

Moreover, businesses should also invest in training staff on the proper techniques for using embossing vacuum bags. This ensures that employees understand how to best utilize these bags, which is crucial for maintaining efficiency and reducing costs associated with damaged goods.