In today's competitive packaging landscape, the choice of materials can significantly influence product integrity and customer satisfaction. An essential component in this regard is the Embossing Vacuum Bag, which has become increasingly popular due to its ability to provide superior protection against external contaminants while enhancing product shelf life. According to a recent industry report by Smithers Pira, the global market for vacuum packaging is expected to reach $35 billion by 2025, with demand driven by food, pharmaceutical, and electronics sectors. The unique embossing technique utilized in these vacuum bags not only aids in air removal but also adds durability and an appealing aesthetic to packaged goods.

As businesses strive to optimize their packaging solutions, understanding the factors that contribute to selecting the best Embossing Vacuum Bag is crucial for ensuring product quality and sustainability. In this blog, we will explore the key considerations for choosing the right Embossing Vacuum Bag tailored to your specific packaging needs.

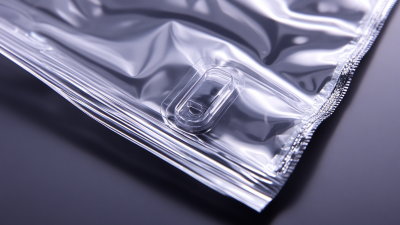

Embossing vacuum bags have gained popularity in the packaging industry due to their ability to provide superior protection for various products. These bags are designed with a unique embossed pattern that enhances airflow during the vacuum sealing process, resulting in a more thorough removal of air. According to a recent industry report, the demand for heat-sealable vacuum bags is projected to grow at a CAGR of 5.2% from 2023 to 2028, reflecting the increasing preference for efficient packaging solutions.

Embossing vacuum bags have gained popularity in the packaging industry due to their ability to provide superior protection for various products. These bags are designed with a unique embossed pattern that enhances airflow during the vacuum sealing process, resulting in a more thorough removal of air. According to a recent industry report, the demand for heat-sealable vacuum bags is projected to grow at a CAGR of 5.2% from 2023 to 2028, reflecting the increasing preference for efficient packaging solutions.

One of the standout features of embossing vacuum bags is their durability. They are made from high-quality materials that resist punctures and tears, ensuring that packaged products remain intact. In fact, data suggests that vacuum-sealed products can extend shelf life by up to 50%, making these bags an ideal choice for food packaging, electronics, and even textile applications.

Tip: When selecting an embossing vacuum bag, ensure it has a high puncture resistance rating and is compatible with your specific packaging machinery for optimal performance. Furthermore, consider the thickness of the bag; thicker bags can offer better protection but may require different sealing procedures.

Flexibility is another key advantage of embossing vacuum bags, allowing for a variety of shapes and sizes of products to be packaged efficiently. This adaptability is crucial in industries where product uniformity is essential, as it minimizes packaging waste and maximizes storage space.

Tip: Always test the sealing process with your specific product to achieve the desired vacuum level and avoid leaks, which can compromise product quality. Investing time in finding the right bag will lead to greater efficiency and cost savings in the long run.

When it comes to choosing the right embossing vacuum bag, understanding the different types available is essential for optimizing your packaging needs. Each type serves distinct purposes, and selecting the right one can greatly enhance the efficiency of your storage solutions. For instance, heavy-duty vacuum bags are designed for long-term storage, accommodating bulkier items like clothing and linens by compressing them to maximize space. According to industry studies, using quality vacuum bags can reduce storage volume by up to 75%, making it a popular choice for those seeking to declutter their living spaces.

Moreover, food preservation plays a critical role in selecting embossing vacuum bags. Specialized bags designed for food storage not only extend the shelf life of perishable items but also maintain their quality and flavor. A recent survey indicated that vacuum-sealed food can last 3 to 5 times longer than items stored in traditional packaging. Therefore, when choosing your embossing vacuum bags, consider your specific needs—be it for clothing, linens, or food—to ensure you make the best investment for long-term efficiency and quality preservation.

When it comes to selecting the right embossing vacuum bag for your packaging needs, several key factors should be considered to ensure optimal performance and efficiency. One of the primary considerations is the material composition of the vacuum bag. According to a report by Smithers Pira, over 45% of packaging professionals cite material strength and durability as essential criteria when making purchasing decisions. Bags made from high-quality, multi-layer plastic can provide enhanced puncture resistance and a better seal, which is crucial for preserving the integrity of the products stored inside.

Another vital factor is the bag size and configuration. Industry insights reveal that improper sizing can lead to compromised vacuum levels and reduced shelf life of packaged goods. The Flexible Packaging Association notes that using correctly sized bags can enhance product preservation by up to 30%. Additionally, businesses should also consider their specific application requirements—whether for food, medical supplies, or industrial products—as this can greatly influence the choice of embossing pattern, which helps in enhancing the suction capabilities of the vacuum bags. Having a clear understanding of these factors will help in making an informed decision tailored to your specific packaging needs.

| Feature | Description | Importance |

|---|---|---|

| Material Type | The type of plastic used (e.g., polyethylene, nylon) influences durability and sealing properties. | High |

| Thickness | Thickness affects strength and resistance to punctures and tears. | Medium |

| Size Options | Availability of various sizes to accommodate different products. | High |

| Seal Strength | The effectiveness of the seal to prevent air leakage and maintain freshness. | Critical |

| Temperature Resistance | Ability to withstand heat for cooking or freezing applications. | Medium |

| Cost | Balance between quality and price to fit budget constraints. | High |

| Eco-friendliness | Consideration of biodegradable or recyclable materials. | Increasingly Important |

When considering packaging solutions, particularly in the context of food preservation, the comparative advantages of embossing vacuum bags over traditional packaging methods become evident. While traditional methods can keep food fresh for a limited time, they often fail to provide the airtight seal that preserves flavor and prevents spoilage. Recent discussions emphasize that while some consumers may feel compelled to invest in expensive vacuum sealing machines, embossing vacuum bags offer an alternative. These bags are equipped to create a vacuum seal manually, eliminating air exposure without additional equipment.

The innovative design of embossing vacuum bags enhances the longevity of stored items, making them an ideal choice for both home users and small businesses. Unlike traditional plastic wraps or containers, which might allow air infiltration, these specialized bags work effectively to keep foods fresher for longer periods. Many users appreciate their ease of use, as they can be sealed by hand and stored confidently without the risk of freezer burn or flavor degradation. For those looking to maintain the quality of their foods without the need for costly machinery, opting for embossing vacuum bags is a practical solution that balances convenience and effectiveness in food storage.

When incorporating embossing vacuum bags into your packaging operations, understanding best practices is essential for optimizing efficiency and maintaining product integrity. First, ensure that you select the right size and type of vacuum bag for your products. This not only facilitates better sealing but also enhances presentation. Consider the thickness of the bag material; thicker bags offer more durability, but may require specific heat settings during sealing.

Tip: Always pre-test the vacuum sealing process with a few samples before full-scale production. This helps identify the ideal vacuum pressure settings and sealing temperature, allowing for adjustments that can prevent potential packaging failures.

Another critical aspect involves maintaining your vacuum sealing equipment. Regular maintenance checks can prolong the life of the machinery and ensure optimal performance. Clean the sealing elements often to avoid contamination that could compromise the seals of your vacuum bags.

Tip: Create a maintenance schedule that includes daily, weekly, and monthly tasks, ensuring that your packaging operations run smoothly and efficiently. By implementing these best practices, you can maximize the benefits of embossing vacuum bags in your packaging process.