When it comes to preserving food and prolonging its freshness, utilizing the right packaging is crucial. One effective solution that has gained popularity is the Embossing Vacuum Roll Bag. These bags are designed to remove air and create a tight seal around your food items, thus extending their shelf life and maintaining flavor. However, to maximize their benefits, it is essential to understand how to use them effectively.

In this article, we will delve into the ultimate tips for using Embossing Vacuum Roll Bags to enhance your food storage practices. From proper sealing techniques to the best materials for vacuum packing, we will cover key strategies that can help you ensure optimal results. Whether you are a home chef looking to store leftovers or someone interested in meal prepping, mastering the use of Embossing Vacuum Roll Bags will transform your food storage approach and reduce waste significantly. Join us as we explore practical steps to make the most of this innovative packaging solution.

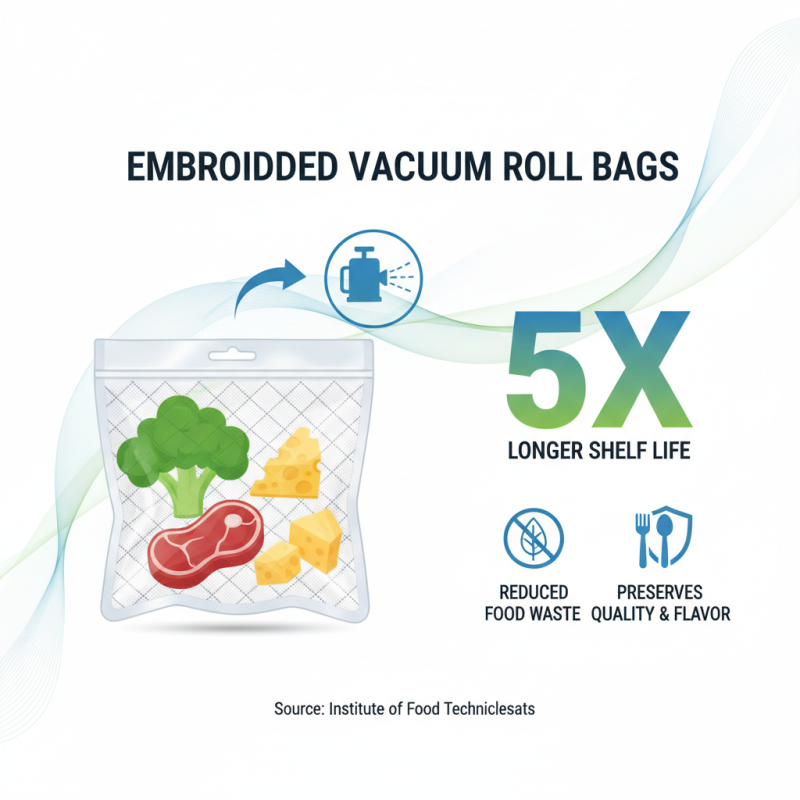

Embossing vacuum roll bags are an invaluable tool in the food packaging and preservation industry. These bags utilize a unique embossing pattern that enhances the vacuum sealing process by allowing air to be efficiently removed from the package. According to a report by the Institute of Food Technologists, vacuum sealing can extend the shelf life of products by up to five times compared to conventional storage methods. This significant enhancement in preservation not only helps in reducing food waste but also maintains the quality and flavor of the products.

In addition to their effectiveness in food preservation, embossing vacuum roll bags offer versatility and convenience for users. Their compatibility with various vacuum sealing machines allows for smooth operation and efficient air extraction. Studies have indicated that packaging food in vacuum-sealed bags can lead to a 30% reduction in spoilage, providing both economic and environmental benefits. Furthermore, these bags are often made from high-quality materials that ensure durability and protect the contents from moisture and contaminants, making them ideal for storing sous-vide meals or marinating foods. Understanding these benefits can lead to better usage of embossing vacuum roll bags, providing both consumers and businesses with a powerful means to enhance food longevity and safety.

When selecting the right size and material for your embossing vacuum roll bags, it is essential to consider your specific storage needs. The size of the bag should correspond to the items you intend to store, ensuring a snug fit that eliminates excess air which can lead to spoilage or damage. For instance, larger items such as bulk vegetables or meat cuts may require wider bags, while smaller items can utilize narrower rolls. Always measure your items before making a purchase to ensure you choose bags that optimize the space and enhance vacuum sealing efficiency.

Material choice is equally important in maximizing the effectiveness of your vacuum roll bags. Look for bags made from durable, multi-layer plastics that offer excellent barrier properties against moisture, oxygen, and light. This helps preserve the freshness of the stored items for an extended period. Embossing vacuum bags are specifically designed to create channels that allow for efficient air removal, making them ideal for both liquid and dry items. When selecting bags, consider the thickness and texture of the material, as thicker bags provide better protection against punctures, while embossed surfaces facilitate better vacuum sealing.

Using embossing vacuum roll bags can significantly enhance your food preservation efforts when done correctly. To get started, ensure you have the right equipment—a vacuum sealer compatible with embossing bags. Begin by cutting the roll to your desired size, allowing extra material for sealing. Preheat the vacuum sealer for optimal performance, ensuring it can properly seal the embossed channels of the bag, as this is crucial for maintaining the vacuum seal quality. According to a report by the Food Packaging Association, using vacuum-sealed bags can extend the shelf life of perishable items by up to five times compared to traditional storage methods.

When using embossing vacuum roll bags, it is essential to pay attention to how you fill the bags. Leave sufficient space at the top—approximately 2-3 inches—to facilitate a proper seal. Overfilling can lead to failure in the sealing process, which compromises the vacuum and could lead to spoilage. Another important tip is to ensure that food items are dry before sealing, as moisture can hinder the vacuum creation and lead to bacterial growth. Studies show that maintaining low moisture content during storage can reduce mold growth by 60% compared to untreated items. Employ these practices to make the most of your embossing vacuum roll bags, keeping your food fresher for longer.

When using embossing vacuum roll bags, avoiding common mistakes can enhance your food preservation experience. One prevalent error is overfilling the bags. Leaving inadequate space for the vacuum seal can result in improper sealing, leading to air pockets that compromise food freshness. To prevent this, make sure to leave enough room—typically about 2 to 3 inches above the food contents—before sealing.

Another frequent mistake is neglecting to check for moisture. If food items are wet before sealing, moisture can get trapped in the bag, promoting spoilage. Always pat dry any moist foods, especially meats or vegetables, before placing them in the bags. Additionally, consider utilizing absorbent materials such as paper towels or specialized absorbent pads within the bags to capture any excess moisture.

For effective use of vacuum roll bags, remember to pre-freeze items that may be prone to crushing, like berries, before vacuum sealing. This will help maintain their shape and texture. Additionally, be mindful of sharp objects that could puncture the bag during the vacuum process. Storing food correctly enhances flavor and texture, ensuring a better experience when you're ready to use your vacuum-sealed items.

| Tip | Common Mistake | Solution |

|---|---|---|

| Use the Right Size of Bag | Using bags that are too small or too large | Choose a bag size that fits the item snugly |

| Pre-Freeze Moist Items | Vacuum sealing wet items without freezing | Quickly freeze items before vacuum sealing to prevent moisture |

| Label Your Bags | Not labeling bags for storage | Use a permanent marker to write the contents and date on the bag |

| Use a Bag Sealer | Not sealing bags properly | Make sure to use a vacuum sealer designed for roll bags |

| Avoid Overfilling | Packing the bags too tightly | Ensure there is space for air to be removed from the bag |

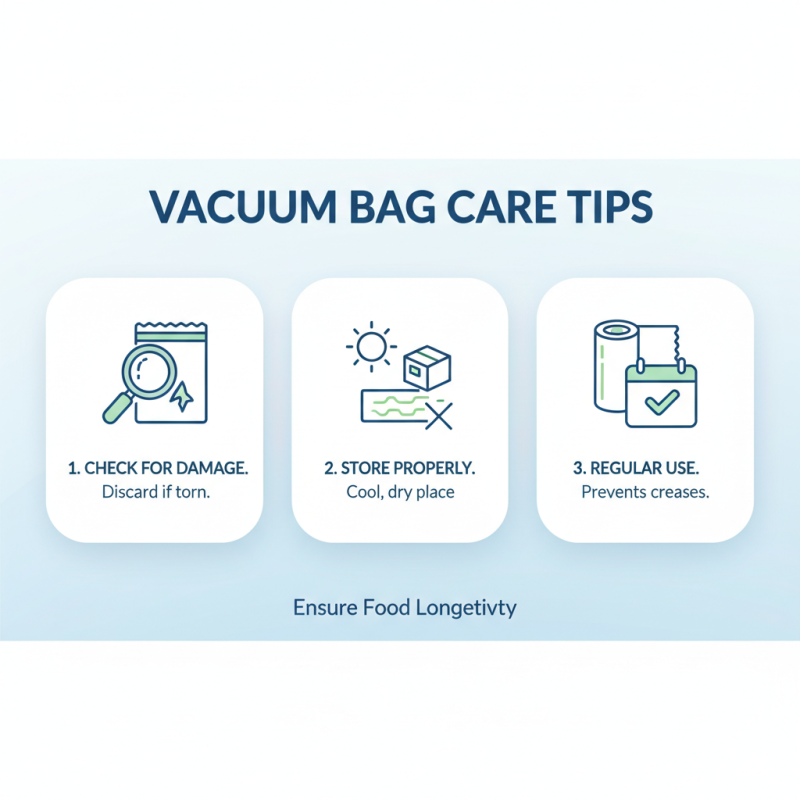

To ensure the longevity of your embossing vacuum roll bags, proper maintenance is crucial. Regularly checking for any signs of wear or damage is the first step. If you notice tears or punctures, avoid using the affected bags, as they may compromise food preservation. Store your vacuum bags in a cool, dry place, away from direct sunlight, to prevent degradation of the material.

Another essential tip is to keep your vacuum roll bags clean. After each use, ensure that the bags are thoroughly rinsed and dried. Food residue can not only lead to unpleasant odors but may also affect the sealing quality in future uses. If you vacuum-seal liquids, consider freezing them first to prevent spills that can damage the bags.

Lastly, always follow the manufacturer’s instructions regarding the temperature limits of the bags. Using them inappropriately can lead to melting or deformation, shortening their lifespan. By following these maintenance tips, you can maximize the effectiveness and durability of your embossing vacuum roll bags for countless uses.